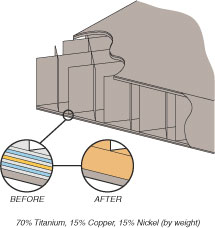

Clad metals that form a braze alloy in situ are used to braze structural components in the engine exhaust systems of Airbus 340-500 and 340-600 long range aircraft. Seven layer material (ni-cu-ni-ti-ni-cu-ni) diffusion brazes internal honeycomb, brackets or braces of Timetal® 21S high strength oxidation resistant beta titanium to a skin of the same material. The precise tolerance control of layers in the EMS cladding process provides consistent braze alloy chemistry, and roll-to-roll bonding is inherently more cost effective than one sheet at a time processes.