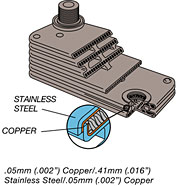

For heat exchangers and other assembled and brazed components, self-brazing materials of copper, aluminum, carbon or stainless steel clad with copper or bronze offer numerous cost-saving advantages over the traditional shim and paste approach. The cladding layer becomes the filler metal eliminating the need for critically positioned shims and paste and the chance of accidental loss or misplacement, improving brazing reliabilty. Fewer component parts means a reduction in manufacturing, assembly and inventory costs. Additional user benefits include manufacturing productivity gains, as well as process yield, quality and product design improvements.